Reducing Lead Times in Custom Metal Fabrication

- Framos Fabrications

- 4 days ago

- 13 min read

Reducing lead times in custom metal fabrication is vital for meeting customer expectations and maintaining a competitive edge. Lead times cover every step from order placement to delivery, and delays can stem from material shortages, disjointed workflows, or mid-process design changes. Here's how manufacturers can address these challenges:

Integrated Workflows: Managing all processes in-house avoids delays caused by outsourcing and enables faster communication and problem-solving.

CNC Machining & Automation: Advanced CNC machines and automation reduce production time, minimise errors, and allow for continuous, unsupervised operation.

Design for Manufacture (DFM): Planning production-friendly designs early prevents rework and ensures smoother processes.

In-Process Quality Control: Regular inspections during production catch issues early, avoiding costly rework and delays.

Framos Fabrications exemplifies these strategies by combining in-house capabilities, CNC technology, and collaborative design. Their streamlined approach enables faster delivery without compromising quality, backed by a quality guarantee and proactive customer service.

Key takeaway: Shorter lead times require a mix of efficient processes, advanced tools, and early-stage planning. By adopting these strategies, manufacturers can deliver on time while maintaining high standards.

Using Integrated Manufacturing Workflows to Reduce Delays

Benefits of Complete Fabrication Services

Handling the entire fabrication process in one place eliminates the communication breakdowns and scheduling hiccups that often crop up in multi-vendor projects. When different companies manage separate stages of production, every handoff introduces potential delays. Design tweaks can take longer to implement, and scheduling conflicts can push deadlines further out.

By keeping all processes under one roof, integrated workflows make things significantly smoother. Design changes? They’re dealt with on the spot, without waiting for external approvals. Engineers can collaborate directly with production teams to address issues as they arise, cutting out the back-and-forth.

This approach doesn’t just save time - it cuts costs too. With no added vendor markups, reduced transport expenses, and more efficient management, overall project costs drop. But perhaps the most appreciated benefit is the time saved, as customers value reliable and predictable delivery schedules.

Consistency in quality is another big win. Unified processes allow for faster internal communication, meaning problems are spotted and resolved quickly. This real-time feedback loop ensures minor issues are tackled before they escalate into major delays.

Framos Fabrications is a great example of how these integrated benefits come to life.

Framos Fabrications' Complete Service Range

Framos Fabrications has streamlined its operations to cover every step of the process - from CAD design to final inspection - under one roof, cutting down on lead times and avoiding the delays that come with multi-vendor projects.

Their design team works hand-in-hand with production staff to ensure designs are optimised for manufacturability before any cutting begins. This collaboration avoids costly redesigns that often occur when external design firms overlook fabrication constraints. Once designs are finalised, CNC operations flow seamlessly without the added delays of transport or external scheduling.

Welding and machining teams also coordinate closely, alternating tasks where needed to create a more efficient workflow. Instead of waiting for all welding to finish before machining begins, they sequence operations to minimise handling time and keep things moving.

The finishing and assembly stages benefit from this same level of direct communication. For instance, if surface preparation reveals an issue that might affect the final product’s appearance, the finishing team can immediately consult with the fabricators to find the best solution. This proactive approach prevents expensive rework and ensures a smoother overall process.

Quality control is another area where Framos Fabrications excels. Inspections aren’t just left until the end - they’re built into every stage. From checking dimensions after cutting to verifying weld quality before machining and confirming surface finishes before assembly, their inspection team ensures problems are caught early and resolved efficiently.

This integrated setup dramatically reduces lead times compared to working with multiple vendors. Framos Fabrications is so confident in its processes that it offers a comprehensive quality guarantee: if a fabrication doesn’t meet drawing specifications, they’ll rework it and provide a 50% credit towards the next order. This level of assurance is only possible because they control every step of production and can address any issues immediately.

03_01_P5 How Can the Manufacturing Lead Time be Reduced

Using CNC Machining and Automation for Faster Production

Integrated workflows, combined with advanced CNC machining and automation, are transforming production cycles, making them faster and more efficient.

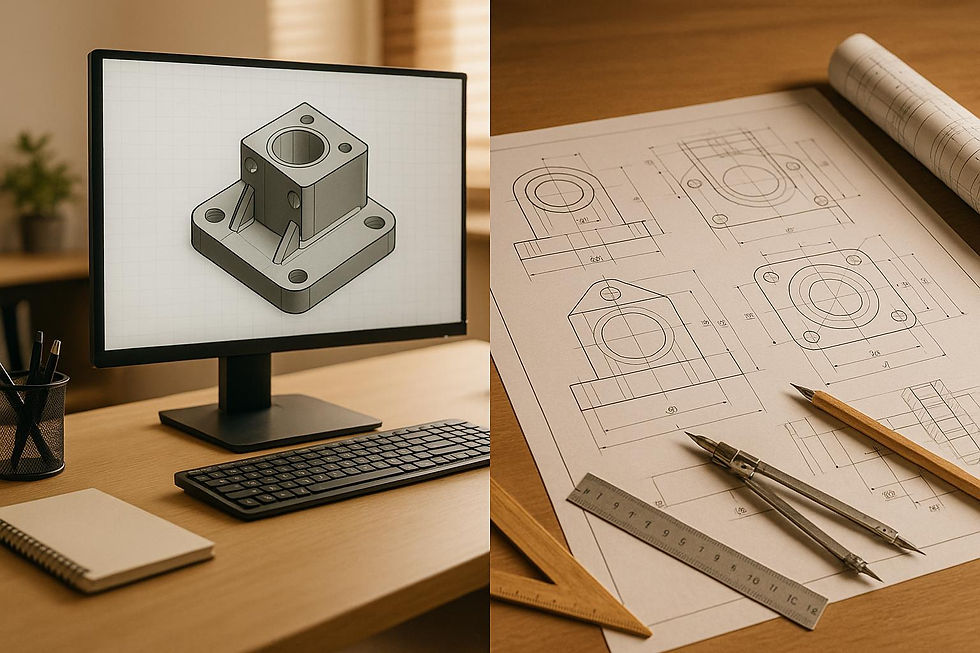

CNC Machining: Precision Meets Speed

CNC machining has revolutionised metal fabrication by delivering unmatched accuracy and speed. Unlike traditional manual methods, CNC machines operate autonomously based on pre-programmed instructions. This allows them to run continuously, even overnight, effectively extending production hours without increasing labour costs.

Once a programme is calibrated, parts are produced with consistent precision, significantly reducing setup times. Complex shapes and designs that would take hours to create manually can be completed in just minutes with CNC technology. And the best part? Every piece comes out exactly the same.

Modern CNC controllers enhance flexibility by storing multiple programmes, enabling quick job transitions. This adaptability allows manufacturers to respond to urgent orders without the hassle of lengthy reconfigurations. Additionally, advanced CNC machines can perform multiple tasks - like drilling, milling, tapping, and contouring - in a single operation. This eliminates the need for manual tool changes, reduces handling time, and minimises positioning errors that could delay production.

Automation: Minimising Errors and Boosting Efficiency

Automation takes CNC machining to the next level by further streamlining production. Automated systems remove the risk of human error and reduce machine downtime. When operators manually input dimensions or adjust settings, even small mistakes can lead to wasted materials and rework. Automation eliminates these risks by following precise digital instructions.

Automated material handling ensures a constant flow of production. Instead of waiting for operators to load and unload parts, automated systems work continuously, which is especially beneficial for high-volume jobs where manual handling could slow things down.

One of the standout benefits of automation is lights-out manufacturing. Machines can operate unsupervised during off-hours, effectively doubling or even tripling production capacity without increasing labour costs. Safety systems and monitoring equipment ensure that machines shut down safely if any issues arise.

Automation also integrates quality control into the process. Automated quality checks immediately identify defects, preventing faulty parts from moving further along the production line. This real-time feedback saves time and reduces the need for costly rework.

Predictive maintenance is another game-changer. By monitoring machine performance, these systems can alert operators to potential issues before they lead to breakdowns, ensuring production stays on track with minimal interruptions.

Framos Fabrications: Leading with CNC Technology

Framos Fabrications has made significant strides by investing in advanced CNC laser cutting and CNC bending equipment, enabling them to reduce lead times and improve efficiency. Their CNC laser cutting systems excel at handling intricate geometries with minimal setup, allowing seamless transitions between jobs throughout the day.

Their CNC bending equipment is equally impressive, capable of storing multiple programmes for various part configurations. This capability means repeat orders can be up and running in minutes, compared to the hours required for manual press brake setups. The precision of CNC bending eliminates the trial-and-error adjustments that often slow down manual processes.

Framos Fabrications also streamlines production by converting customer CAD files directly into machine programmes. By having their design team work closely with CNC operators, they optimise cutting and bending sequences from the outset, ensuring a smooth and efficient production process.

Material efficiency is another area where their CNC equipment shines. Automated nesting software arranges parts on sheet metal to minimise waste, reducing the number of sheets needed. This often allows jobs to be completed using materials already in stock, bypassing potential delays from material procurement.

The integration of their CNC laser cutting and bending operations creates a seamless workflow. Parts move directly from cutting to bending without unnecessary handling or storage, keeping projects on schedule and reducing overall processing time. Framos Fabrications demonstrates how advanced technology can transform production into a faster, more efficient process.

Design for Manufacture: Planning Production from the Start

Speeding up production begins with a well-thought-out design. This idea ties directly into our integrated manufacturing strategy. By focusing on Design for Manufacture (DFM) from the very beginning, we ensure that production flows smoothly, avoiding delays caused by overly complex features, unexpected material changes, or the need for rework. DFM turns potentially challenging designs into production-ready plans, enabling a seamless transition through the manufacturing process. This design-first approach enhances the efficiencies gained from integrated workflows.

The Benefits of Design-for-Fabrication

Making smart design decisions early on can significantly shorten production timelines. Features like intricate cutouts, tight radii, or excessive bends often require extra setup and programming time. Simplifying these elements makes designs easier to programme and faster to produce.

Another key advantage lies in standardising components. When hole sizes, dimensions, and other design elements adhere to standard specifications, there's no need for custom tooling or special setups. This means production can start immediately using existing tools and programmes, avoiding delays caused by creating and testing custom solutions.

Collaboration between design teams and fabricators during the early stages is crucial. When fabricators are involved in the design phase, they can provide valuable feedback on aspects like bend allowances, material selection, and hole placement. This input helps refine designs, ensuring they are fabrication-friendly and free from unnecessary complexities that could slow down production.

These strategies also align with the benefits of integrated workflows. For example, efficient nesting reduces material waste and speeds up cutting operations. Often, jobs can be completed using materials already in stock, avoiding the need for lengthy procurement processes. With an optimised design in place, prototyping becomes even more effective in validating the final approach.

Prototyping and First-Article Inspection

Prototyping and first-article inspection are essential for identifying and addressing design issues early, keeping production on track. These steps allow adjustments to be made before full-scale production begins, saving time and costs.

Prototyping is particularly useful for testing how designs perform during actual fabrication. While a design may look perfect on-screen, real-world fabrication can reveal hidden challenges. Prototyping catches these issues early, allowing for timely adjustments to the design.

It also provides an opportunity to refine the design further. Features that seemed necessary during planning might turn out to be redundant, and tolerances that appeared critical could be relaxed without compromising functionality. These insights help simplify the final design and make production more efficient.

First-article inspection serves as a thorough check of the manufacturing process. By carefully examining the first completed part, manufacturers can confirm that dimensions, tolerances, and specifications align with production methods. Any discrepancies found at this stage can be addressed through process tweaks rather than altering the design, keeping the project on schedule.

This inspection step also ensures consistent quality throughout production. By identifying and resolving potential issues with the first article, manufacturers can prevent quality problems from affecting subsequent parts, reducing rework and avoiding delays.

At Framos Fabrications, the design team works hand-in-hand with CNC operators to streamline cutting and bending processes from the very start of a project. By converting customer CAD files directly into machine programmes, they ensure that designs are ready for manufacturing before production even begins. This close integration between design and production eliminates the trial-and-error adjustments often seen in traditional workflows, helping to reduce lead times and improve efficiency.

Quality Control Methods to Prevent Delays

Our integrated manufacturing approach is strengthened by quality control measures designed to prevent delays. By identifying potential issues early, quality control avoids costly rework and keeps production schedules on track. Even in well-organised workflows, unexpected variables can affect part quality, but systematic inspections help maintain consistency and momentum. This proactive approach is seamlessly aligned with efforts to minimise lead times.

In-Process Inspections to Maintain Standards

Instead of waiting until the end of production, in-process inspections allow manufacturers to monitor quality at every stage. This ensures that any deviations from specifications are caught and addressed immediately, preventing defective parts from advancing further in the process.

For example, during CNC laser cutting, operators check kerf width, edge smoothness, and dimensions to ensure cut quality. If laser power or assist gas pressure changes, these inspections quickly detect the issue, avoiding the need to scrap parts and restart production.

Welding operations also benefit from continuous monitoring. Visual inspections of weld penetration, bead appearance, and heat-affected zones help identify parameter inconsistencies early. Adjustments to settings like current, voltage, or travel speed can then be made on the spot, preserving structural integrity without halting production.

In bending operations, particular attention is given to springback and angle accuracy. By measuring the initial bent parts and comparing them to specifications, operators can fine-tune press brake settings to account for material variations. This prevents angular errors that could otherwise require time-consuming rework.

Quality control plays a critical role in ensuring precision, durability, and consistency. Combining automated systems with skilled oversight enhances the process. For instance, coordinate measuring machines (CMMs) verify critical dimensions during production, while experienced operators use their expertise to identify subtle issues that machines might overlook. This dual approach ensures both technical accuracy and practical insight.

Framos Fabrications' Quality Guarantee

Framos Fabrications takes quality control a step further with a robust guarantee that reflects their confidence in their processes. This guarantee reassures customers that their projects will meet exact specifications and be delivered on time.

Covering every stage of fabrication - from initial cutting to final assembly - Framos Fabrications' guarantee promises to rework any job that does not meet the specified requirements at no additional cost. Additionally, the company offers a 50% credit towards the customer's next order if quality issues occur.

Thorough inspections after fabrication and finishing ensure that defects are identified early. These checks cover dimensions, weld quality, and surface finishes, ensuring every job meets the required tolerances. By addressing potential issues upfront, Framos Fabrications prevents rework delays and maintains production schedules.

To further build customer confidence, Framos Fabrications provides free samples alongside their quality guarantee. This allows customers to assess both quality and production capabilities before committing to larger orders. It’s a practical way to demonstrate the company’s commitment to delivering consistent, high-quality results.

Comparing Different Lead Time Reduction Methods

Reducing lead times can be tackled through a variety of methods, each with its own strengths and challenges. Some strategies require substantial upfront investments with long-term benefits, while others deliver quicker results. To make the best choice, manufacturers need to weigh these trade-offs, considering their production scale, project complexity, and available resources.

Pros and Cons of Lead Time Solutions

Here's a comparison of key strategies for reducing lead times:

Each method offers unique benefits, and combining them often yields the best results.

Integrated workflows help ensure smooth transitions between production stages but depend heavily on clear communication and process standardisation. CNC automation excels in repetitive, precision tasks, cutting down setup times and reducing manual errors. However, its high cost and reduced adaptability to mid-production design changes are notable drawbacks.

Design for manufacture focuses on addressing potential production issues early, reducing delays later in the process. While this approach requires collaboration during the initial stages, it can prevent costly rework. Similarly, in-process quality control identifies issues early, ensuring tighter tolerances and minimising defects, though it may slightly increase production times due to added inspections.

Advanced planning systems, powered by modern software, optimise scheduling, material usage, and bottleneck identification. Their success, however, hinges on the quality of input data, making accurate and reliable information a critical factor.

Combining Strategies for Maximum Impact

Framos Fabrications provides a great example of how blending these methods can streamline production and reduce lead times. For instance, pairing CNC automation with integrated workflows can improve both speed and coordination. Similarly, combining design-for-manufacture principles with in-process quality control creates a seamless flow from initial design to final delivery.

Budget considerations often dictate which methods are adopted first. Starting with cost-effective solutions that deliver quick wins can build a solid foundation for future investments in more advanced systems like automation and integrated workflows. By thoughtfully combining approaches, manufacturers can achieve faster, more efficient production processes tailored to their needs.

Conclusion: Achieving Faster, More Reliable Fabrication

Reducing lead times in custom metal fabrication calls for a well-rounded strategy that blends cutting-edge technology, efficient processes, and thoughtful planning. This is exemplified by the approach taken by Framos Fabrications.

Technology and Automation for Precision and Speed

Advanced tools like CNC machining and automation play a pivotal role in ensuring both speed and accuracy. These technologies enable continuous production with fewer errors, all while keeping labour costs in check. Yet, relying solely on technology isn’t enough to address the complexities of fabrication.

The Importance of Early Collaboration

Engaging fabricators during the design phase can prevent delays and costly rework. By identifying potential issues early, production can proceed smoothly. This collaborative approach aligns seamlessly with integrated workflows and automated systems, ensuring a more efficient process. Paired with streamlined supply chain management and strong supplier relationships, it also guarantees materials are ready when needed.

Integrated Services for Better Control

Framos Fabrications’ in-house capabilities allow them to oversee every stage of production, reducing the risk of delays. This integration enables them to handle a variety of project sizes, with lead times ranging from 1–2 weeks for smaller jobs to 4–6 weeks for larger ones.

"We guarantee that we will manufacture to the manufacturing drawings provided. If you were to ever find a discrepancy, then we would be sure to rectify any errors on our part free of charge. We can typically achieve this within 48 hours, depending on the size of the project."

Their commitment to precision is backed by a 100% inspection process, ensuring products meet exact specifications without compromising speed. By offering quotes within 24 hours and accepting DXF and STP files directly, they eliminate unnecessary delays while upholding their promise of accuracy.

Simplifying Through Consolidation

Working with a single fabrication partner simplifies the process, cutting down on delays and improving both reliability and efficiency.

The secret to faster fabrication lies in removing inefficiencies, not cutting corners. By combining advanced technology, collaborative design efforts, and rigorous quality control, manufacturers can meet tight deadlines without sacrificing standards. As Tim Wrinch, Managing Director of Framos Fabrications, puts it:

"Delivering Expert Metal Fabrications Right First Time, on Time, Every Time."

Ultimately, achieving shorter lead times is about finding the right mix of strategies tailored to your needs. With the right partners, it’s clear that speed and quality can go hand in hand, driving excellence in metal fabrication.

FAQs

How does combining all processes within one facility help reduce lead times in custom metal fabrication?

Keeping all processes - like design, cutting, and finishing - under one roof can significantly cut down lead times in custom metal fabrication. When outsourcing is off the table, delays caused by transportation and coordinating with multiple vendors are no longer an issue.

An in-house setup gives manufacturers more control over the entire production process. This means smoother handoffs between stages, faster problem-solving, and a more seamless workflow. The result? Faster delivery times, improved efficiency, and better quality in the final product.

How do CNC machining and automation help reduce lead times and improve precision in metal fabrication?

CNC machining combined with automation is a game-changer for reducing lead times and achieving precise results in metal fabrication. By relying on computer-guided programs, CNC machines handle tasks like cutting, assembling, and finishing with unmatched speed and precision. This significantly reduces the need for manual intervention, cutting down on human error and simplifying production processes.

Automation takes things a step further by allowing operations to run continuously, fine-tuning cutting speeds, and delivering consistent results. Together, these technologies not only speed up production but also maintain a high standard of quality, enabling manufacturers to hit tight deadlines without compromising on accuracy.

Why is Design for Manufacture (DFM) important for avoiding delays and rework in metal fabrication?

Design for Manufacture (DFM) plays a crucial role in avoiding delays and reducing the need for rework in metal fabrication. The concept revolves around creating part designs that are tailored to fit the capabilities and limitations of the manufacturing process. When designs are aligned with production methods, workflows become more efficient, errors are minimised, and overall productivity improves.

By addressing key elements like material selection, tolerances, and fabrication techniques right from the start, DFM ensures smoother operations. This forward-thinking approach not only helps manufacturers stick to tight deadlines but also avoids the expense and hassle of making last-minute adjustments or reworking parts further down the line.

Comments